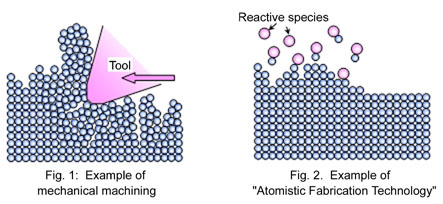

"Atomistic Fabrication Technology" is a novel manufacturing technology which fully utilizes physical and chemical phenomena with atomistic and electronic understanding. Figure 1 shows an example of conventional mechanical machining. In the case of mechanical machining, many defects are introduced when pushing the tool on the workpiece surface, and then atoms on the workpiece surface are removed by the displacement and multiplication of such defects. Therefore, many defects remain on the workpiece surface after mechanical machining. Machining accuracy is considerably affected by disturbances, such as thermal deformation and external vibration, because removal depth is dependent on the cutting depth of the tool. So, it is very difficult to manufacture precision products by mechanical machining.

On the contrary, in the case of atomistic fabrication technology, surface atoms are naturally removed by chemical reaction caused by reactive species as shown in figure 2. So, there is no deformed layer on the workpiece surface. Machining accuracy does not depend on the accuracy of the machine, because removal depth is dependent on the dwelling time of the source of the reactive species. Therefore, a very high-precision product can be easily manufactured if the physical or chemical phenomenon, which is used for removal reaction, is stable and moreover the material of the object is homogeneous.

|